What is a Slitter Cutter Machine and How Does It Work?

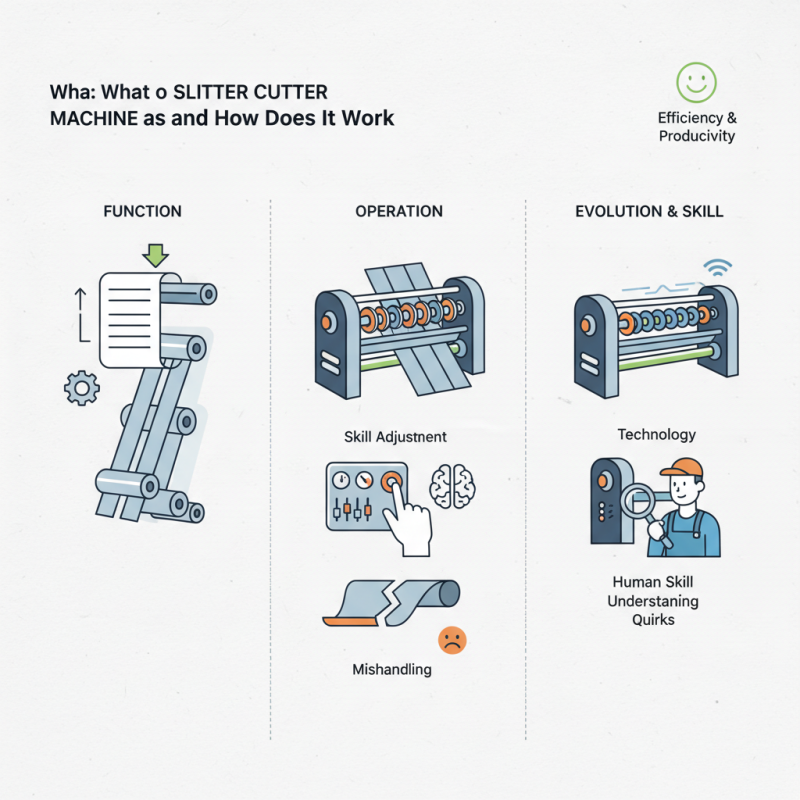

In the world of manufacturing, the "Slitter Cutter Machine" plays a crucial role. This precision tool slices materials into thinner strips or sheets. According to John Harrison, an industry expert, "Efficiency in cutting is essential for productivity." His insight highlights the machine's importance.

Operating a Slitter Cutter Machine requires skill. Workers must adjust settings based on material type and thickness. Trouble can arise if the machine is improperly calibrated. Mishandling can lead to waste and downtime, affecting production.

Yet, the technology behind slitter cutters evolves. New features offer improved precision and speed. Still, operators must remain vigilant. Every machine has its quirks, and understanding these imperfections is key to success. This blend of technology and human skill defines the industry.

Definition and Purpose of a Slitter Cutter Machine

A slitter cutter machine is essential in various industries. It is used primarily for cutting wide materials into narrower strips. This is crucial for manufacturers dealing with materials like paper, film, and metal. The ability to customize widths helps optimize production.

According to recent industry reports, the slitting and rewinding market is expected to grow by 5.3% annually through 2027. This demand stems from increased automation in manufacturing processes. Slitter cutter machines not only enhance efficiency but also reduce waste. By ensuring precise cuts, manufacturers can save material costs. However, improper adjustments can lead to inconsistencies. This highlights the need for skilled operators.

In certain cases, a lack of maintenance can hinder performance. Regular checks on blades and settings are vital. Industry experts note that many operators overlook this critical aspect. As a result, their output may suffer. Ensuring optimal machine function directly impacts overall productivity and material quality. As slitter cutter machines evolve, staying informed about advancements is key.

Components of a Slitter Cutter Machine

A slitter cutter machine is an essential tool in manufacturing. Its primary function is to cut large rolls of material into smaller, more manageable widths. Understanding its components helps in grasping how it operates.

The main parts of a slitter cutter machine include the blades, unwind stand, and rewind stand. The blades can be circular or straight, designed for precise cuts. They must be sharp to ensure clean edges. The unwind stand holds the material roll in place as it feeds through the machine. This stand can sometimes be adjusted to accommodate different roll sizes.

The rewind stand collects the trimmed material, ensuring it is neatly wound. This stand is crucial for maintaining tension in the material during the cutting process. Additionally, the guiding system helps align the material precisely. Misalignment can lead to uneven cuts, which is something to avoid in production. Each component works together, but issues can arise if one part underperforms or malfunctions. Regular maintenance is important to ensure efficiency and accuracy in operations.

Working Principle of a Slitter Cutter Machine

A slitter cutter machine is an essential tool in various industries. It is designed to cut large rolls of material into narrower strips. This process is crucial for further manufacturing and packaging. But how does it really work? The heart of the machine is its blade system.

The slitter cutter operates by feeding a roll into the machine. As the material moves forward, rotating blades slice it into desired widths. The speed and precision of this operation are vital for efficiency. Operators need to adjust settings carefully. Misalignment can lead to uneven cuts and wasted material. Sometimes, the blades do not make a clean cut. This can cause frayed edges, impacting quality.

Safety is another concern. Improper use can lead to accidents. Workers must remain vigilant while operating the machine. Regular maintenance is required to keep it running smoothly. Dust and debris can accumulate, affecting performance. Clear guidelines should be established for usage. However, the reliance on this machine can sometimes overshadow proper training for operators. It’s crucial to find a balance between machine efficiency and human oversight.

Applications of Slitter Cutter Machines in Various Industries

Slitter cutter machines play a crucial role in many industries. They are designed to cut large rolls of material into narrower strips. This process is vital for manufacturers who require specific widths for their products. In the packaging industry, for example, slitter cutters help create films and labels with precise dimensions. The accuracy these machines provide enhances product quality.

In the textile industry, slitter cutters are used to cut fabric rolls. This ensures that garments and other textile products maintain consistency in size. Similarly, in the metalworking sector, these machines slice metal sheets into manageable sections. This versatility makes slitter cutters essential across various fields. However, achieving the perfect cut can be challenging. Operators must often recalibrate machines for different materials. This can slow production and lead to waste if not managed carefully.

Additionally, slitter cutters require regular maintenance. Neglect can lead to malfunctions, affecting output. Workers must stay vigilant to ensure peak performance. Despite these challenges, the benefits of using slitter cutter machines far outweigh the drawbacks. Their ability to adapt in various industries showcases their importance. They continue to evolve, responding to the changing demands of manufacturing.

What is a Slitter Cutter Machine and How Does It Work? - Applications of Slitter Cutter Machines in Various Industries

| Industry | Material Processed | Common Applications | Benefits |

|---|---|---|---|

| Packaging | Plastic, Paper | Slitting and rewinding rolls for packaging | Increased efficiency, consistent thickness |

| Textiles | Fabrics, Non-wovens | Cutting fabric into specific widths | Minimal waste, precise cuts |

| Food Industry | Foils, Films | Packaging for food products | Longer shelf life, hygienic processing |

| Automotive | Rubber, Films | Cutting materials for car interiors | High precision, customized sizes |

| Electronics | Foam, Plastic Sheets | Produce components for devices | Reduced manufacturing costs, faster production |

Maintenance and Safety Considerations for Slitter Cutters

Slitter cutter machines are essential in various industries for cutting large rolls of materials into smaller widths. For effective operation, maintenance and safety are crucial. Regular maintenance ensures these machines run smoothly and safely. A report from the Machinery Safety Management Board indicates that 25% of machine accidents result from poor upkeep.

One vital tip is to establish a routine inspection schedule. Check components like blades and bearings regularly. Dull blades not only affect cut quality but can also lead to injuries. Keeping the cutter clean is equally important. Dust and debris can cause malfunctions. Use appropriate cleaning agents for each part.

Safety training is important for operators. 40% of industry injuries stem from inadequate operator training. Ensure that all users understand how to operate the machine properly. Provide protective gear such as gloves and goggles. Encourage reporting of any irregular sounds or malfunctions immediately. Address these issues promptly to avoid bigger problems.

Furthermore, it’s critical to keep the work area organized. Clutter increases the risk of accidents. Operators should be aware of their surroundings while working. Remind them to maintain focus and avoid distractions. Recognizing the signs of wear and tear on the equipment can prevent costly breakdowns. Regular assessments of blade sharpness and machine alignment are necessary for optimal performance.

Slitter Cutter Machine Performance Analysis

This chart represents key performance metrics of a slitter cutter machine including speed, total output length, waste percentage, and downtime hours. Monitoring these metrics helps in optimizing the performance and maintenance of slitter cutters.

English

English  Français

Français