Exploring the Future of Best CNC Laser Cutting in the 2025 Technology Landscape

As we approach the year 2025, the landscape of CNC laser cutting technology is poised for significant transformation, driven by rapid advancements in automation and digitalization.

According to a recent market analysis, the global CNC laser cutting machine market is projected to reach $5 billion by 2025, with a compound annual growth rate (CAGR) of approximately 7% from 2020 to 2025. This growth is underscored by increasing demand across various sectors, including automotive, aerospace, and electronics, where precision and efficiency are paramount.

According to a recent market analysis, the global CNC laser cutting machine market is projected to reach $5 billion by 2025, with a compound annual growth rate (CAGR) of approximately 7% from 2020 to 2025. This growth is underscored by increasing demand across various sectors, including automotive, aerospace, and electronics, where precision and efficiency are paramount.

The integration of AI and IoT technology in CNC laser cutting systems will not only enhance operational efficiency but also reduce waste, positioning businesses to adapt to the evolving manufacturing requirements.

This blog will explore the future trends, challenges, and opportunities in the CNC laser cutting industry, equipping stakeholders with essential insights and tips to thrive in this dynamic environment.

Understanding CNC Laser Cutting Technology: Key Innovations to Expect by 2025

CNC laser cutting technology is poised for significant advancements by 2025, driven by several key innovations that promise to enhance precision, speed, and efficiency. According to a report by ResearchAndMarkets, the global CNC laser cutting machine market is expected to reach $4.2 billion by 2025, growing at a CAGR of 5.8% from 2020. This surge is largely attributed to the increasing demand for highly accurate cutting processes in various industries such as automotive, aerospace, and electronics.

One of the most noteworthy innovations on the horizon is the integration of AI and machine learning into CNC laser cutting systems. These technologies will allow machines to adapt in real-time, optimizing parameters for better performance based on material type and thickness. Additionally, advancements in fiber laser technology are making cutting systems faster and more efficient, reducing operational costs. For instance, reports suggest that fiber lasers can cut materials at speeds up to five times faster than traditional CO2 lasers, making them an attractive choice for manufacturers looking to enhance productivity. As we approach 2025, these innovations will not only reshape the CNC laser cutting landscape but also set new standards for manufacturing efficiency and quality.

Future Innovations in CNC Laser Cutting Technology (2025)

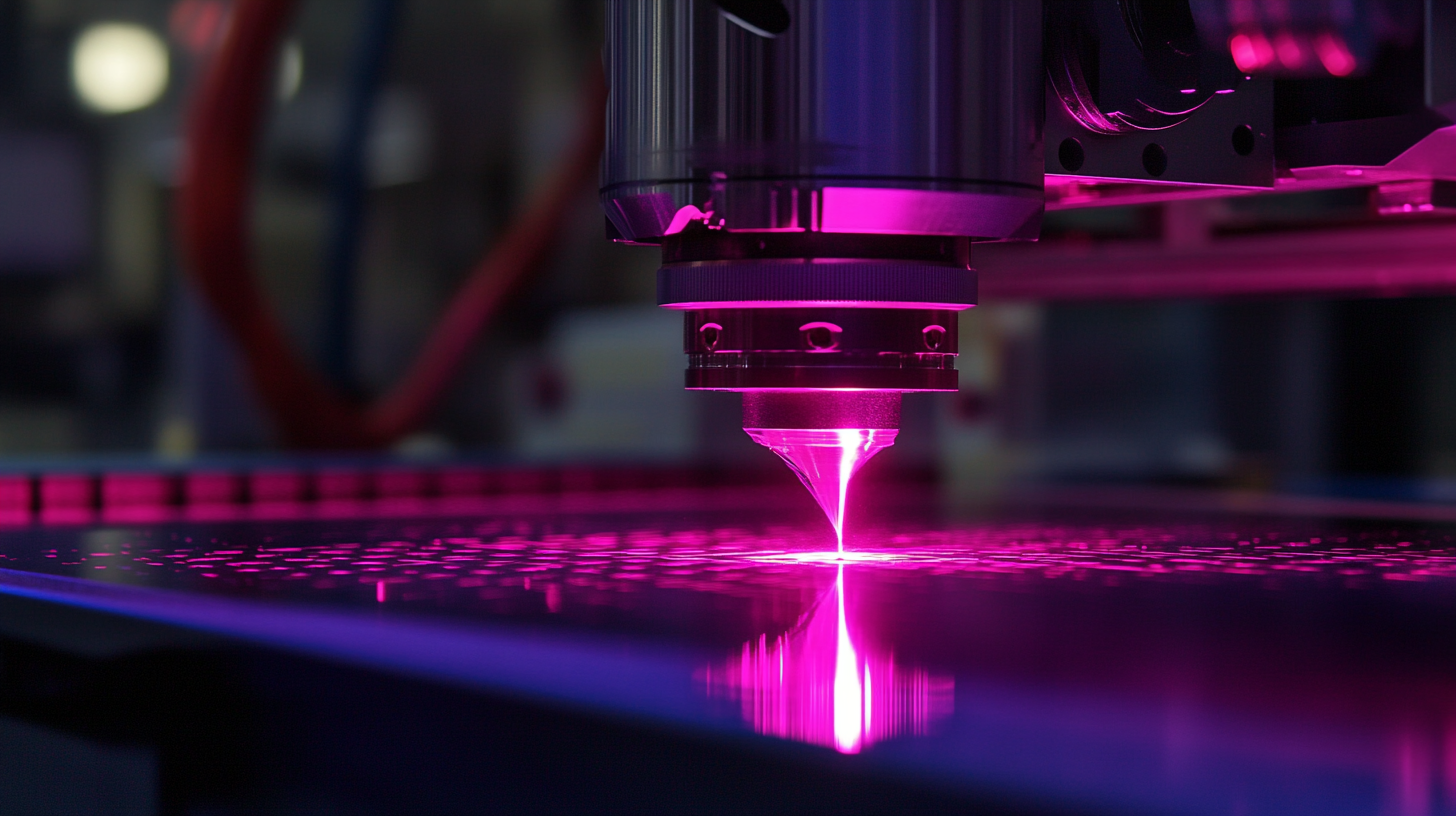

Advantages of High Precision and Efficiency in CNC Laser Cutting

In the rapidly evolving landscape of CNC laser cutting technology, the advantages of high precision and efficiency stand out, especially as we approach 2025. The current market is experiencing significant growth, driven by advancements in laser processing equipment. With various technology types such as fiber lasers, CO2 lasers, and solid-state lasers, manufacturers are able to offer enhanced performance and versatility. The COVID-19 pandemic may have impacted many sectors, but it also accelerated the adoption of automation and innovative processing solutions, leading to a surge in demand for high-speed laser cutting tools.

Imagine a scene where a laser precisely drills eight holes in a 1mm stainless steel plate within one second. This remarkable efficiency showcases the capabilities of modern CNC laser cutting systems, which not only save time but also reduce material waste. The shift towards faster and more accurate processing methods is crucial for businesses looking to maintain competitiveness in a challenging marketplace. As cutting-edge technologies like laser scanning and next-generation advancements emerge, the future of CNC laser cutting promises enhanced productivity and performance, setting new standards for manufacturing excellence.

Exploring the Future of Best CNC Laser Cutting in the 2025 Technology Landscape

| Feature | Details | Benefits | Application Areas |

|---|---|---|---|

| High Precision | Laser cutting with accuracy within ±0.01 mm. | Reduces material waste, improves part quality. | Aerospace, automotive, electronics. |

| Efficiency | High cutting speeds with minimal downtime. | Increased productivity, faster turnaround time. | Manufacturing, prototyping. |

| Versatility | Can cut a variety of materials including metals, plastics, and wood. | Adaptable to different industries and projects. | Architecture, art, custom fabrication. |

| Cost-Effectiveness | Lower operational costs due to reduced waste and fast production times. | Improves profitability for manufacturing businesses. | Small to large-scale production. |

| Technological Integration | Integration with CAD software for enhanced design capabilities. | Streamlines workflow and reduces errors. | Engineering, design studios. |

Sustainable Practices in CNC Laser Cutting: Eco-Friendly Benefits

As we look towards 2025, the landscape of CNC laser cutting technology is poised for a significant transformation, particularly in the realm of sustainability. The integration of eco-friendly practices in this cutting-edge manufacturing process is not just a trend but a necessity driven by growing environmental concerns. Modern CNC laser cutting machines are increasingly being designed to minimize energy consumption and reduce waste, thereby aligning production with eco-conscious principles.

One of the most notable eco-friendly benefits of CNC laser cutting is its precision. Unlike traditional cutting methods that often generate considerable scrap material, laser cutting utilizes a focused beam of light that results in cleaner cuts and reduced excess waste. This inherent accuracy not only conserves materials but also allows businesses to optimize their operations by lowering costs associated with raw material procurement. Additionally, advancements in technology are enabling the use of alternative power sources, such as solar energy, further enhancing the sustainability of CNC laser cutting processes. As these technologies continue to evolve, they will undoubtedly play a crucial role in shaping a greener future for the manufacturing industry.

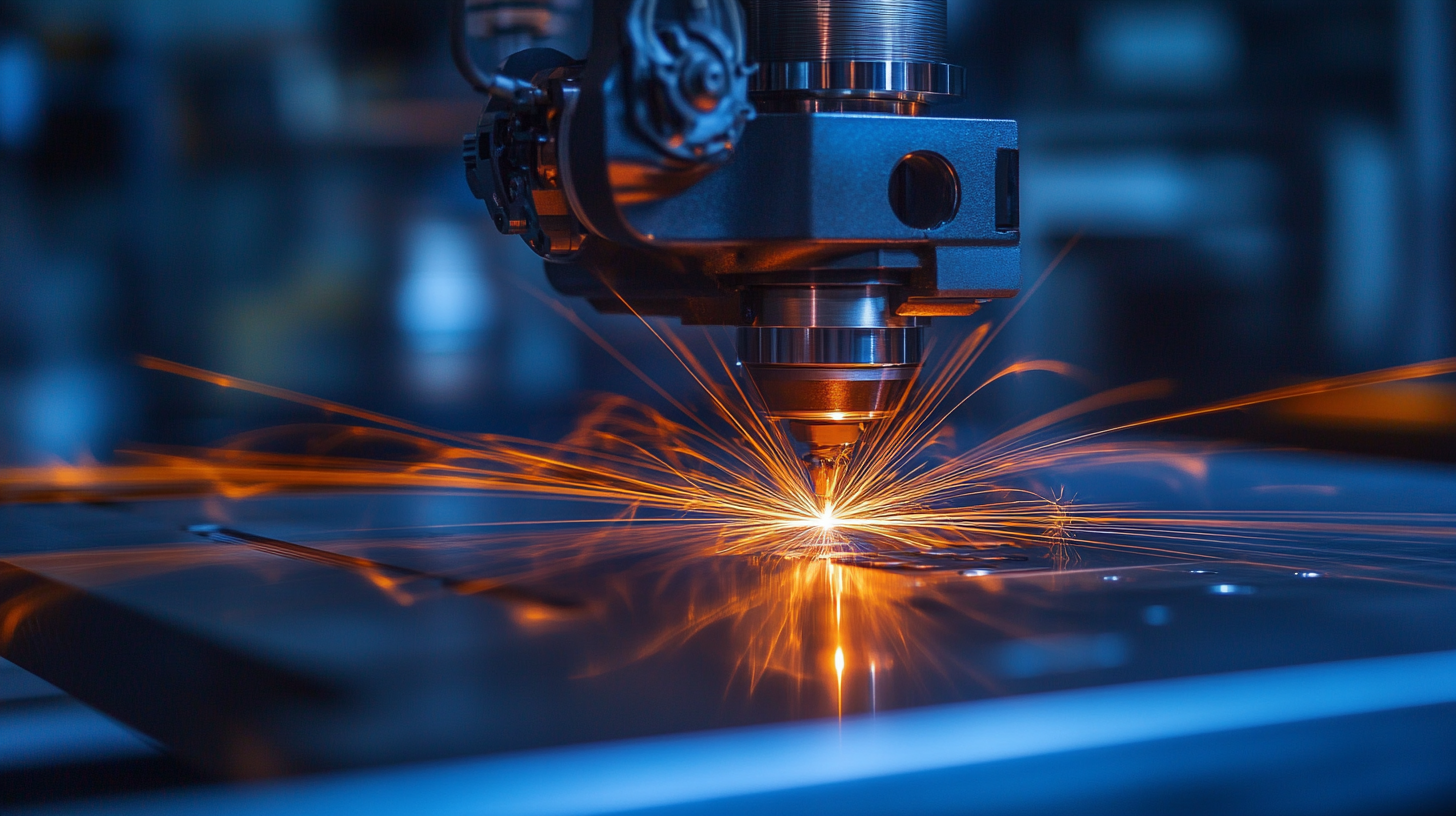

The Role of Automation and AI in Enhancing CNC Laser Cutting Processes

As we look towards 2025, the integration of automation and AI in CNC laser cutting processes stands to revolutionize the manufacturing landscape. New advancements in machine design and cutting technologies are paving the way for more efficient and precise operations. Recent developments in AI solutions demonstrate significant productivity gains, with companies reporting improvements of at least 20% in their machining tasks. This is largely due to intelligent systems that analyze historical data to optimize cutting parameters, ensuring smoother workflows and reducing material waste.

As we look towards 2025, the integration of automation and AI in CNC laser cutting processes stands to revolutionize the manufacturing landscape. New advancements in machine design and cutting technologies are paving the way for more efficient and precise operations. Recent developments in AI solutions demonstrate significant productivity gains, with companies reporting improvements of at least 20% in their machining tasks. This is largely due to intelligent systems that analyze historical data to optimize cutting parameters, ensuring smoother workflows and reducing material waste.

Moreover, the rise of sophisticated laser cutting machines, equipped with state-of-the-art technology, underscores the growing demand for high-precision applications across various industries. The market for laser cutting machines is projected to expand substantially, driven by innovations that enhance speed and accuracy. The unveiling of next-generation machines featuring automation capabilities at industry events indicates a commitment to pushing the boundaries of what is possible in laser cutting, making the future of CNC technology both exciting and transformative.

Market Trends: Demand for CNC Laser Cutting Across Various Industries in 2025

In 2025, the demand for CNC laser cutting technology is poised to expand significantly across various industries, driven by advancements in automation and the growing need for precision manufacturing. Reports indicate that the global CNC laser cutting market is expected to reach approximately $5 billion, reflecting a compound annual growth rate (CAGR) of 7% from 2023 to 2025. This surge is attributed to increased adoption in sectors such as automotive, aerospace, and electronics, where the need for intricate designs and high-quality cuts is paramount.

Moreover, the aerospace sector, in particular, is projected to see the most robust growth, with an estimated market share increase of over 25% in laser cutting applications. This growth is fueled by the industry's demand for lightweight components made from advanced materials, which require specialized cutting techniques that CNC lasers provide.

Additionally, the electronics industry is witnessing an uptick in the use of CNC laser cutting for producing complex circuit boards and microelectronic components, further elevating the technology's importance in modern manufacturing. As businesses strive for operational efficiency and reduced production times, CNC laser cutting technology remains at the forefront of innovation in 2025.

English

English  Français

Français