How to Choose the Right Metallurgical Bridge Crane for Your Needs?

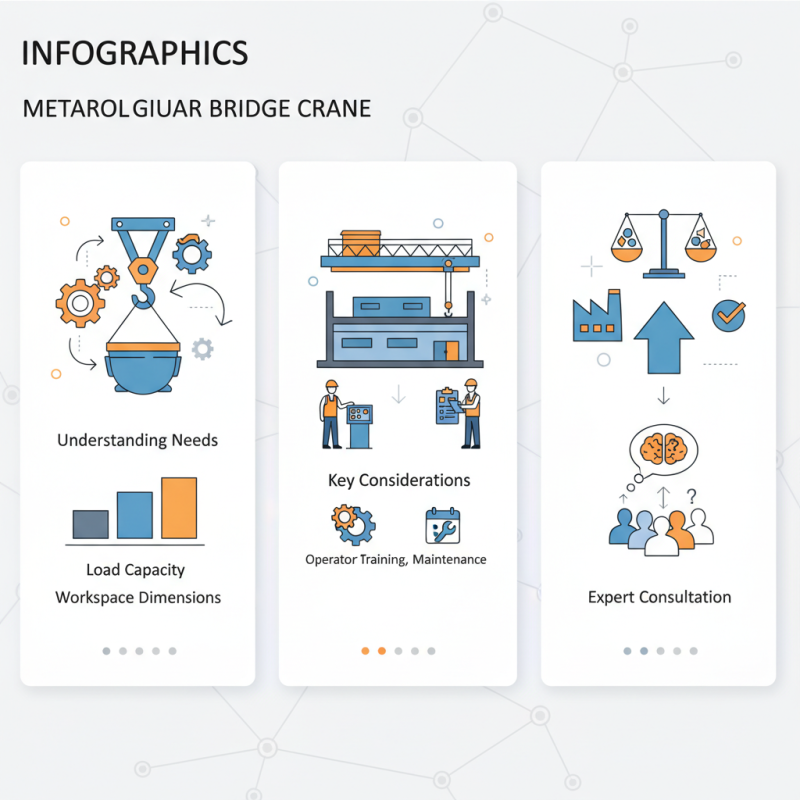

Choosing the right Metallurgical Bridge Crane is crucial for smooth operations in steel production and similar industries. According to John Smith, a leading expert in crane technology, “Selecting the appropriate crane can significantly improve efficiency and safety.” His words resonate deeply within the metallurgical field. Understanding the specific needs of your operation is the first step.

Metallurgical Bridge Cranes come in various sizes and configurations. Each option caters to different load capacities and workspace dimensions. It is essential to consider these factors before making a choice. A mismatch can lead to inefficient processes or even dangerous situations. The wrong crane may not lift materials safely. This sometimes results in costly downtime.

While features like lifting capacity and span are vital, so are the less obvious factors. For instance, consider operator training and maintenance needs. Operators should be familiar with the specific crane model. Maintenance schedules must align with production timelines. Overlooking these aspects can jeopardize safety and productivity. Selecting the right Metallurgical Bridge Crane often requires balancing numerous factors, and even seasoned professionals might not have all the answers.

Understanding Metallurgical Bridge Cranes and Their Applications

Metallurgical bridge cranes are vital in industries like steel manufacturing and metal processing. They serve the purpose of transporting heavy materials effectively. A recent industry report indicates that the demand for these cranes has increased by 20% over the past five years. This rise is largely attributed to the growing need for automation and efficiency in manufacturing processes.

When choosing a metallurgical bridge crane, it's essential to evaluate its design and load capacity. Many cranes have specific ratings, often ranging from 5 to 200 tons. This capacity affects how efficiently materials can be moved. Additionally, the lift height and span should match the operational space. An ill-fitting crane can lead to workflow disruptions.

However, many companies still overlook crucial factors. Some may prioritize cost over quality, leading to higher maintenance costs. There are also concerns about safety, as approximately 15% of crane accidents are due to improper selection. Detailed inspections and proper training are often neglected. Taking the time to choose the right crane can significantly reduce risks and enhance productivity.

Key Factors to Consider When Selecting a Metallurgical Bridge Crane

When selecting a metallurgical bridge crane, consider several key factors. The weight capacity is crucial. Ensure the crane can lift the heaviest loads in your facility. Inspect the materials used in construction. High-quality materials enhance durability and safety. Additionally, check the design for any space constraints. Proper maneuverability is essential in tight work environments.

Another critical aspect is the operational speed. A faster crane can improve efficiency. However, too much speed may compromise safety. Evaluate how often the crane will be used. If it’s for continuous operation, durability becomes even more important. Keep in mind the type of controls, too; intuitive controls will ease operation for staff.

Lastly, maintenance requirements should not be overlooked. Regular maintenance can prevent unexpected downtimes. Consider the availability of parts and service. Factor in training needs; staff should understand the crane’s functionality well. Balancing these considerations can lead to a more effective choice. Reflect on your facility’s unique needs while making this decision.

Evaluating Load Capacity and Reach Requirements for Your Operations

When choosing a metallurgical bridge crane, load capacity and reach requirements are critical. Various industries report different standards. For example, a heavy-duty crane may need to lift over 20 tons. The American Society of Mechanical Engineers (ASME) suggests that careful calculations are crucial. A common mistake is underestimating the load. This can lead to accidents.

In terms of reach, consider the operational layout. The crane's span must cover the entire working area. Industry reports indicate that a span of 20 to 30 feet is typical. However, some operations may require over 50 feet. Insufficient reach can slow production. It’s important to measure the distances accurately.

Also, reflect on future needs. Load requirements can change. Companies often experience growth, so planning for increased capacity is wise. An analysis from industry experts highlights that 60% of businesses wish they had opted for a higher load capacity initially. This gap can lead to costly upgrades later. Always consider both immediate and long-term operational goals.

Assessing Safety Features and Compliance Standards for Cranes

When selecting a metallurgical bridge crane, safety features should be a priority. The crane must comply with local standards. This ensures the protection of workers and equipment. Look for features like overload protection and emergency stop buttons. Without these, accidents can occur easily. Consider the environment where the crane will operate. Extreme temperatures or dust can affect functionality.

Compliance standards vary by region. It's crucial to familiarize yourself with these regulations. Sometimes, outdated equipment may not meet the latest requirements. This can lead to vulnerabilities. Regular inspections are necessary. They help identify any wear and tear. Waiting too long can lead to unsafe conditions. A crane may not work as intended without proper checks.

Think about the user experience as well. Operators need to be trained thoroughly. They should understand all the safety mechanisms. A misunderstanding can be costly. It's not just about buying the right equipment; it's about keeping everyone safe. Always reflect on how safety features integrate into daily operations. Your decisions can impact the overall safety culture in the workplace.

Safety Features and Compliance Standards in Metallurgical Bridge Cranes

Understanding Maintenance Needs and Costs for Long-Term Use

When selecting a metallurgical bridge crane, understanding maintenance needs is crucial for long-term usability. Regular maintenance can significantly extend the lifespan of your equipment. The main factors include wear and tear, lubrication, and inspections. According to industry reports, up to 30% of crane downtime is due to maintenance issues. Ignoring these needs can lead to costly repairs and unsafe operating conditions.

Tips: Keep a maintenance log. Document every service and repair. This provides insight into patterns of wear and helps in budgeting for future maintenance costs. Regular inspections should not be overlooked. They are vital for identifying potential problems before they escalate.

Be aware that maintenance costs can vary. On average, operators can expect to budget around 5-10% of the crane's initial purchase price annually for upkeep. Some facility managers report that inadequate maintenance led to unexpected failures, resulting in lost productivity. It’s clear: a proactive approach is better than a reactive one when it comes to managing crane health.

English

English  Français

Français