What are the Benefits of Stainless Steel Woven Wire Mesh?

stainless steel woven wire mesh has become essential in various industries. According to a 2023 report by the Global Wire Mesh Association, the market for stainless steel woven wire mesh is expected to grow by 8% annually. This growth highlights its importance in applications like filtration, architecture, and automotive industries.

Expert John Smith, a prominent figure in wire mesh innovation, states, “stainless steel woven wire mesh offers unparalleled durability and versatility.” This is crucial as industries demand materials that can withstand harsh environments. The mesh's resistance to corrosion and high temperatures makes it a preferred choice for many applications.

However, it is important to consider some challenges. While stainless steel woven wire mesh is resistant to many elements, the initial investment can be high. Businesses must weigh longevity against upfront costs. Finding the right balance is vital for optimal use in production processes.

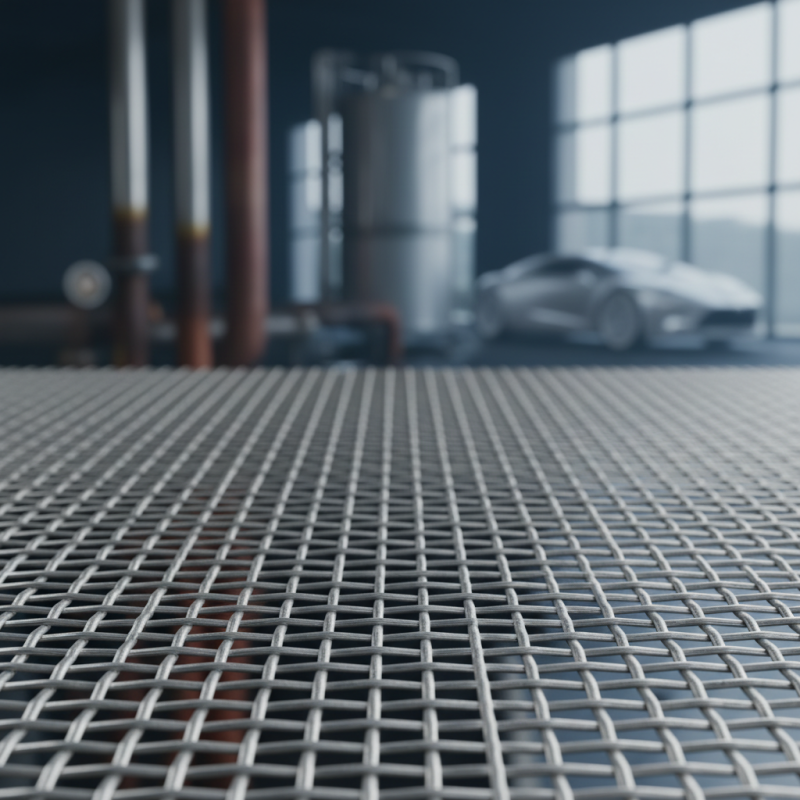

Benefits of Stainless Steel Woven Wire Mesh in Industrial Applications

Stainless steel woven wire mesh serves as an essential component in various industrial applications. Its strength and durability make it ideal for filtration systems. This mesh is resistant to corrosion, which prolongs its lifespan. Many industries rely on its performance in harsh environments. The ability to withstand high temperatures is an added advantage. It is also easy to clean and maintain.

In manufacturing processes, stainless steel woven wire mesh is used in conveyor belts and screens. It provides an open structure that allows for optimal airflow. This is especially beneficial in drying processes. The precision of mesh openings ensures uniformity in the sieving process.

However, the initial cost may be a concern for some businesses. They need to weigh the long-term benefits against upfront expenses.

While it is a reliable choice, selecting the right specification is crucial. Not all meshes fit every application perfectly. Some may find that incorrect choices lead to inefficiencies. Hence, careful consideration is necessary. Testing different types can help to discover the best fit. This suggests that even experienced users should remain open to experimentation.

Durability and Corrosion Resistance of Stainless Steel Mesh Materials

Stainless steel woven wire mesh offers impressive durability. This material withstands harsh conditions, making it ideal for various applications. It resists wear and tear, providing a long-lasting solution. The mesh is often used in construction, filtration, and even art projects. Many users appreciate how it holds up in both outdoor and indoor environments.

Corrosion resistance is another key benefit. Stainless steel does not rust easily. It can endure exposure to moisture and harsh chemicals. This property makes it suitable for food processing or marine environments. Over time, some may start to notice discoloration, but it's often superficial. Regular cleaning can maintain its appearance effectively. Careful maintenance is essential to maximize its lifespan.

Applications of Stainless Steel Woven Wire Mesh Across Various Industries

Stainless steel woven wire mesh has diverse applications across various industries. In construction, it serves as an essential reinforcement material. This mesh helps in creating durable structures and enhances safety. According to a report by MarketsandMarkets, the stainless steel mesh market is expected to grow by over 5.2% annually, highlighting its increasing use.

In food processing, stainless steel woven wire mesh is crucial for filtration. It ensures hygiene and minimizes contamination. The FDA encourages the use of stainless steel due to its corrosion resistance and easy cleaning properties. Industries are relying more on stainless steel mesh for maintaining product quality. Equipment in dairy and meat processing often employs this mesh to filter impurities.

Tips: When selecting stainless steel mesh, consider the weave pattern. A tighter weave offers better filtration but may reduce flow rates. It's essential to find a balance for your needs. Keep in mind that not all stainless steel is created equal. Subpar quality can lead to premature failure, which needs reflection.

In aerospace, the mesh plays a role in component manufacturing. It's used for screens and protective barriers. The balance of lightweight and strength is critical in this industry. However, despite its benefits, some sectors may overlook its potential. Increased awareness can drive its adoption and enhance performance in various applications.

What are the Benefits of Stainless Steel Woven Wire Mesh? - Applications of Stainless Steel Woven Wire Mesh Across Various Industries

| Industry | Application | Benefits |

|---|---|---|

| Food Processing | Filtration of liquids | Corrosion resistance, easy cleaning |

| Pharmaceuticals | Equipment protection | Chemical resistance, sterile properties |

| Construction | Reinforcement for concrete | Strength, durability |

| Mining | Screening during mineral processing | Toughness, resistance to wear |

| Aerospace | Component manufacturing | Lightweight, high strength |

Comparative Cost-Benefit Analysis of Stainless Steel vs. Other Mesh Types

When considering various types of mesh materials, stainless steel woven wire mesh often stands out. Its durability and resistance to corrosion make it a popular choice across industries. In contrast, other materials may offer lower initial costs but can incur higher long-term expenses due to frequent replacements.

For instance, aluminum mesh is lighter, but it lacks the strength of stainless steel. This results in more frequent maintenance or replacement. Similarly, plastic meshes may seem cost-effective at first, but their susceptibility to UV damage leads to deterioration over time. Stainless steel’s lifespan can justify the higher upfront expense. It allows for saving on not just the material costs but labor as well.

However, the decision is not always straightforward. Some projects may not require the durability that stainless steel offers. In these cases, alternative materials might be more suitable, despite their potential shortcomings. Weighing immediate budget constraints against long-term benefits is crucial. An informed choice often leads to better outcomes.

Unique Features of Stainless Steel Mesh: Strength, Flexibility, and Longevity

Stainless steel woven wire mesh stands out due to its unique properties. It combines strength and durability, making it ideal for various applications. This mesh can support heavy loads without bending or breaking. It’s made from high-quality stainless steel, ensuring resistance to rust and corrosion. This feature enhances its longevity, making it a reliable choice for outdoor use.

Flexibility is another remarkable aspect of stainless steel mesh. It can be woven in different patterns, allowing designers to create custom solutions. These designs can range from simple to complex, suiting various needs. Even with its robust nature, the mesh can be molded to fit specific shapes. This adaptability opens doors to innovative uses in architecture and engineering.

However, not all applications benefit from stainless steel mesh. In certain environments, the initial cost may seem high. Users must also consider weight and installation challenges. While the mesh is resilient, it can be difficult to handle in large sheets. These factors require careful thought. Balancing durability and practicality could lead to better material choices in some cases.

English

English  Français

Français