Alloy Powder Grader Tips for Optimal Performance and Selection?

The selection and performance of Alloy Powder Graders are vital for the advancement of manufacturing technologies. Industry reports indicate that appropriate grading can enhance the properties of materials significantly. For instance, a study by the International Journal of Powder Metallurgy found that precise grading improves particle flow and reduces waste material by up to 30%.

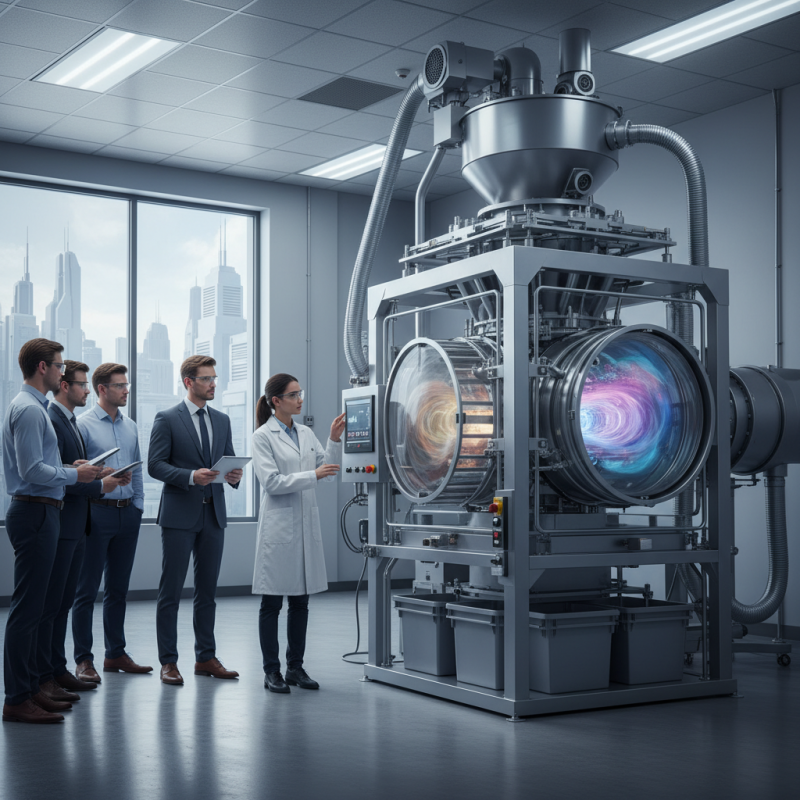

Dr. Emily Chen, a respected expert in powder metallurgy, states, "The right Alloy Powder Grader can make a substantial difference in production efficiency." This reinforces the importance of understanding the specific needs for various applications. Grading alloys isn't simply a routine task; it demands expertise and insight into the materials involved.

In the competitive landscape of manufacturing, overlooking the choice of an Alloy Powder Grader can hinder production quality. Many companies grapple with optimizing their processes. They may even miss opportunities for innovation due to inadequate grading practices. Selecting the right equipment requires careful consideration and continual evaluation of one’s grading equipment and process.

Alloy Powder Grader: Understanding Its Importance in Material Selection

The alloy powder grader plays a crucial role in selecting the right materials for various applications. Accurate grading impacts the quality of final products. Carefully considered powder selection can enhance performance attributes like strength and durability.

Different alloys have unique properties tailored for specific needs. However, not all grading systems are perfect. Some may overlook subtle variations in particle size and composition. This can result in suboptimal material performance. A thorough understanding of grading techniques helps avoid these pitfalls.

Moreover, operators must remain vigilant. Equipment settings require constant adjustment based on the material’s behavior. Routine maintenance is essential to ensure consistent output. Inconsistent grading could lead to serious production issues. Therefore, ongoing training and awareness are vital. Understanding the alloy powder grader’s importance is key to achieving optimal performance.

Alloy Powder Grader Tips for Optimal Performance and Selection

| Parameter | Description | Optimal Range |

|---|---|---|

| Particle Size Distribution | The range of sizes of particles in the powder. | 10 - 50 µm |

| Bulk Density | Volume occupied by a unit mass of powder. | 0.5 - 1.0 g/cm³ |

| Flowability | The ease with which the powder can flow. | Good (Hausner ratio < 1.25) |

| Moisture Content | Amount of water present in the powder. | < 0.5% |

| Chemical Composition | The types and amounts of elements in the alloy. | Varies by application |

| Thermal Conductivity | Ability to conduct heat. | > 200 W/mK |

| Tensile Strength | Resistance of the powder to being pulled apart. | > 500 MPa |

Key Factors Influencing the Performance of Alloy Powder Grading Systems

When considering alloy powder grading systems, several key factors can significantly affect performance. One of the most critical elements is the particle size distribution. A well-graded alloy powder ensures consistent properties in the final product. Too much variation in size can lead to unpredictable behaviors during processing. For example, larger particles might not fully merge during sintering, potentially impacting structural integrity.

Another significant factor is the material’s flowability. This characteristic directly influences how efficiently the powder can be processed. Powders that clump together can cause blockages, affecting the overall production rate. A powder with good flowability allows for uniform feeding into machines, enhancing productivity. However, achieving the perfect balance between flowability and other properties can be challenging. In some cases, additives may be necessary.

Lastly, environmental conditions play a role in performance. Humidity can cause oxidation in metal powders, altering their characteristics. This might result in poor sintering or lower mechanical properties. Manufacturers must monitor storage conditions closely to avoid degradation. These factors highlight the complexities that come with selecting the right alloy powder grading system.

Alloy Powder Grader Performance Metrics

Industry Standards and Classifications for Alloy Powder Grading

When selecting alloy powders, understanding industry standards is crucial. These standards provide clarity on grading processes. Different classifications exist for various applications. Each type has specific requirements regarding particle size, composition, and morphology. These parameters are critical for performance.

Grading often involves several methods. Sieve analysis is one of the most common. This technique evaluates particle size distribution. It helps in determining how the powders will behave in different environments. However, not all methods are foolproof. Sometimes, they can misrepresent the actual characteristics of the material.

Knowing what you prioritize in alloy powders is essential. Factors like density and flowability can significantly affect performance. Recognizing industry classifications helps buyers make informed decisions. However, it’s easy to overlook details. Too often, people focus solely on price and availability. This can lead to suboptimal choices that affect productivity.

Best Practices for Optimal Performance in Alloy Powder Grading

When grading alloy powders, achieving optimal performance is crucial. Understanding the properties of the material can significantly impact the final product. Pay attention to particle size and distribution. A consistent size leads to better flow and packing efficiency. Finer particles may increase reactivity but might also cause agglomeration.

Choosing the right grading technique is vital. Methods like sieving or laser diffraction can provide accurate results. However, some may struggle with ease of use or accuracy. Relying solely on one technique could lead to misleading data. It might be beneficial to combine methods for better reliability.

Another area to consider is environmental factors. Humidity can affect powder performance. Ensure proper storage to prevent moisture absorption. Regular checks and adjustments to the grading process can further enhance outcomes. Reflect on these practices to identify improvement areas. Performance is not static; it requires continuous monitoring and adaptation.

Advancements in Alloy Powder Grading Technology and Their Impact

Alloy powder grading technology has seen significant advancements lately. These innovations have made it easier to achieve precise measurements and consistent results. Newer methods focus on laser diffraction and image analysis. They promise better accuracy than traditional sieving techniques.

The impact of these advancements cannot be ignored. Automated systems reduce human error. However, they may overlook subtle inconsistencies. This creates a reliance on machine accuracy that demands careful monitoring. Operators must stay vigilant for any deviations.

Despite improvements, challenges remain. Not all alloys behave in predictable ways. Variability in particle shape and size can lead to inaccuracies. Therefore, understanding material characteristics is vital. Technological progress offers exciting opportunities, but caution is necessary as we embrace these tools.

English

English  Français

Français